Facilities

Qingdao, China

Brighton’s Qingdao 800 acre facility will be China’s first private sector heavy foundry and forging company, established to capitalize on the technical and managerial advantages Brighton brings to the melting, casting, forging, machining and welding / fabrication of finished components for Generation 3 nuclear power plants, the petrochemical industry and other heavy industrial uses.

Brighton has broken ground on 350,000 m2 of factory floor space for melting and forging, with some machining capacity. The crane lifting capacity will be 750 tons and the crane under hook will be 30 meters. The facility will cast 650-ton ingots, with finished pieces of up to 400 tons.

Phase I will employ 1,030 workers led by a Korean team of leading forging industry executives. An adjoining and similarly sized site has been reserved for Phase II. The Phase II factory will be 350,000 m2, used for machining and welding / fabrication of finished forged components. This phase will employ 1,070 workers. An additional 10 square kilometers has been reserved for independent factories anticipated to supply the over 30,000 components necessary for Generation 3 nuclear reactors, for petrochemical pressure vessels and other components, providing work for nearly 25,000 employees.

Brighton is establishing a 1000-acre facility on the coast near the port city of Vizag, in the state of Andhra Pradesh. The facility is being established as a joint venture effort with one of India’s leading manufacturers of machined components to its civilian nuclear power program, as well as to its aerospace, defense and other sectors.

The India facility will mirror the size and capabilities of the Qingdao factories, and will supply the Indian and international markets with forged Generation 3 nuclear and petrochemical bushings and finished pressure vessels components, as well as other forged components.

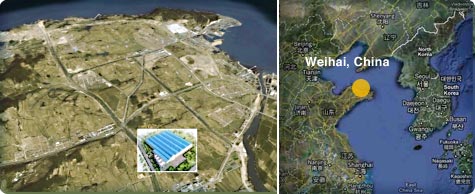

Eastern Heavy Machinery Co., Ltd. (“Eastern Heavy‿, in Weihai City, Shandong Province, was completed in December 2009, at a total investment of USD 84 million, The site is 330,000 square meters (81 acres). Eastern Heavy includes a machine shop of 32,000 sq/m (344,000 sq/ft), and offices and worker housing of approximately 16,000 sq/m (172,000 sq/ft). The machine shop is being outfitted with ten Schiess Brighton ultra large machine tools, including gantry mills, vertical turning and boring mills, horizontal boring mills, horizontal lathe and one of the world’s largest gear “hobbers‿(to build large gears for cement and other manufacturing facilities). The factory will manufacture the larger machine tools for nuclear power, petrochemical, thermal power, windmills, shipbuilding, and cement making industries, and other users of ultra-large forged steel components.